Bending metal tubes and profiles is an essential operation for metalworking workshops, whether for the automotive, metal construction, furniture, or boilermaking industries. To obtain precise and reproducible curves, it is not enough to have high-performance machines: you also need to master the settings, understand the behavior of the materials, identify common errors, and adopt appropriate solutions.

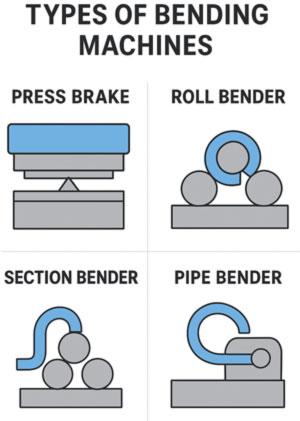

Machines used for bending

Garant Machinerie offers a wide range of metal machine tools adapted to all needs:

- Rolling machines with 3 or 4 rollers: perfect for bending thin tubes and profiles with medium to large bend radii.

- Robotic bending CNC machines: Ideal for repetitive series and complex shapes, they allow you to memorize programs and reproduce identical bends.

- Mechanical or hydraulic folders: suitable for square or rectangular profiles, they guarantee a precise angle while preserving the section.

Trick : Choose your machine based on the diameter, thickness and type of profile to be bent to maximize precision and durability.

Essential adjustments for a perfect bend

To achieve optimal results, it is crucial to master several parameters:

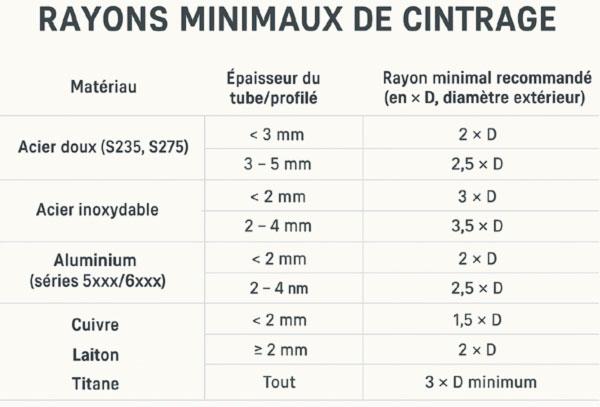

- Bending radius: proportional to the diameter and thickness of the tube to avoid folds and crushing.

- Lubrication: reduces friction and prevents cracks, especially on stainless steel, aluminum and sensitive alloys.

- Speed and pressure: adjusted according to the rigidity of the material and the complexity of the shape.

The use of CNC machines allows these parameters to be programmed and ensures error-free repetitive production, which is ideal for industrial workshops.

Materials and constraints

Each material has its own constraints

- Mild steel: tolerates tight radii and resists deformation well.

- Stainless steel and aluminum: require wider radii to avoid cracks and deformations.

- Square or rectangular profiles: require specific dies and counter punches to keep the section intact.

Trick : Testing a sample before mass production allows for fine-tuning and avoid costly defects.

Common mistakes and solutions

The most common mistakes in bending tubes and profiles include:

- Creases or crushes: often due to a spoke that is too tight or insufficient lubrication.

- Breaks or cracks: caused by excessive pressure or unsuitable material.

- Local deformations: linked to poor adjustment of the rollers or a lack of counter-support.

Solutions: Precise adjustment of machines, selection of suitable tools, correct lubrication and operator training. Regular maintenance of equipment also extends its lifespan and ensures consistent quality.

Case studies and industrial applications

Bending of tubes for metal railings and stairs: Roller rolling machines allow for regular radii and aesthetic finishes.

Profiles for automotive chassis: CNC machines ensure precision and repeatability, essential for quality control.

Manufacture of metal furniture: Hydraulic bending machines with specific tools guarantee perfect angles and avoid crushing square or rectangular profiles.

Why choose Garant Machinerie?

With our expertise and comprehensive range of bending, rolling, and CNC machines, we assist our customers in selecting the right machines, ensuring optimal setup, and providing operator training. Each machine is tested to ensure precision, reliability, and longevity.

Discover our profile bending machines And benders to optimize your bends.

Contact our experts for personalized advice: Request a quote.

FAQ – Bending tubes and profiles

Q1: What is the bending radius for a 50 mm diameter steel tube?

A: Generally, the radius should be at least 1.5 times the diameter to avoid creases or cracks.

Q2: Can all materials be bent with the same machine?

A: No. Rigid materials like stainless steel or aluminum require specific settings and sometimes adapted machines.

Q3: How to avoid deformations on square profiles?

A: Use suitable dies and counter punches, lubricate properly and respect the recommended minimum radius.