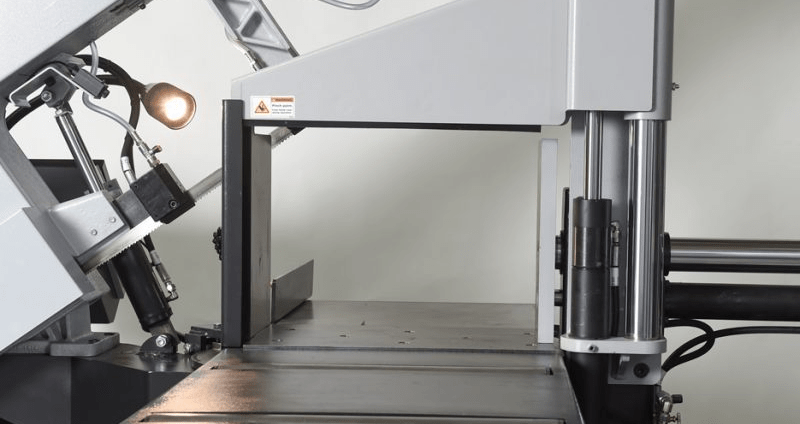

Variable speed drive control

The blade speed can be adjusted directly from the control Panel, eliminating the need to manually adjust belts or pulleys. Saving time and comfort for the operator.

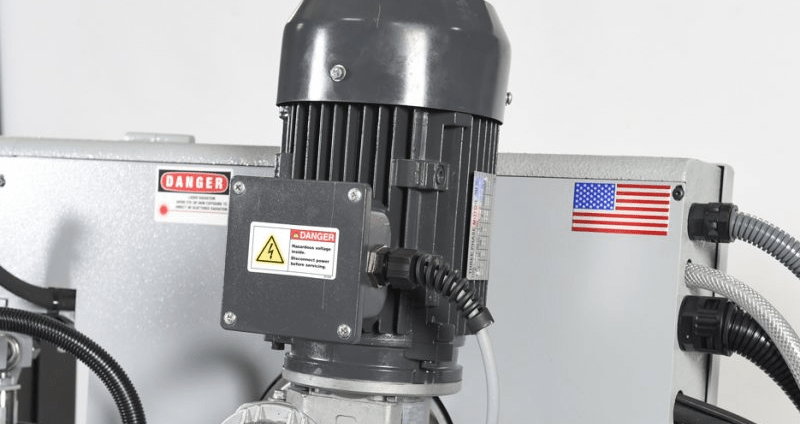

Direct drive motor

The engine is directly connected to the reducer, which eliminates torque losses due to belts or pulleys. The result: more power transmitted and less maintenance.

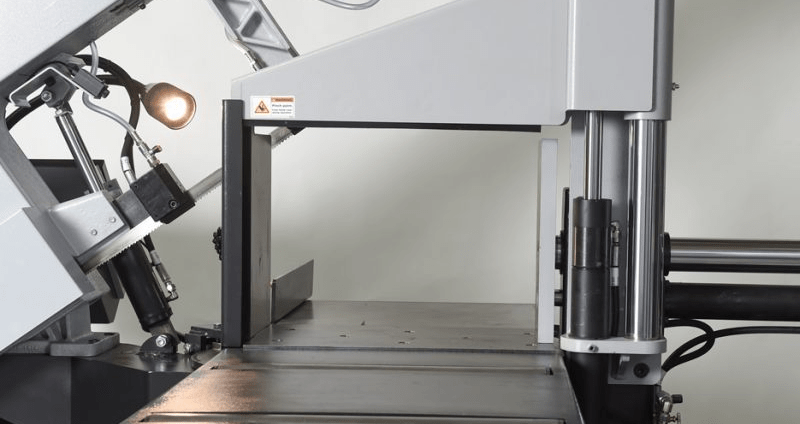

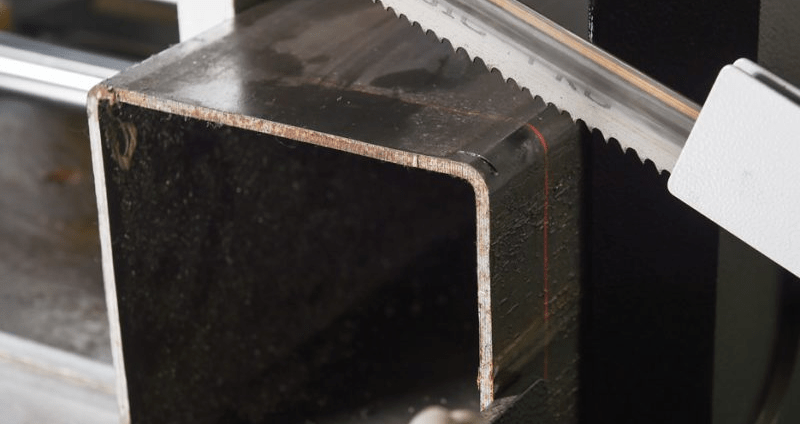

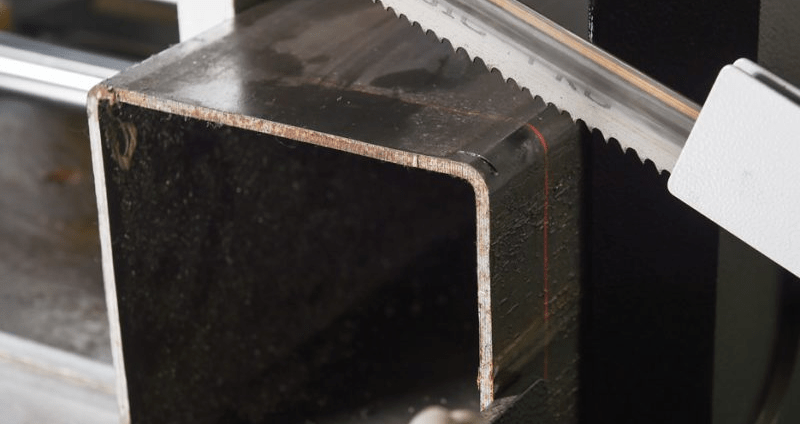

Laser cutting line

Projects a precise line on the part, allowing the operator to position the material accurately before cutting. Ideal for perfectly aligned straight or miter cuts.

Integrated roller table

There 36 inch roller rear table effectively supports the incoming material, facilitating the positioning of long bars and improving work safety.