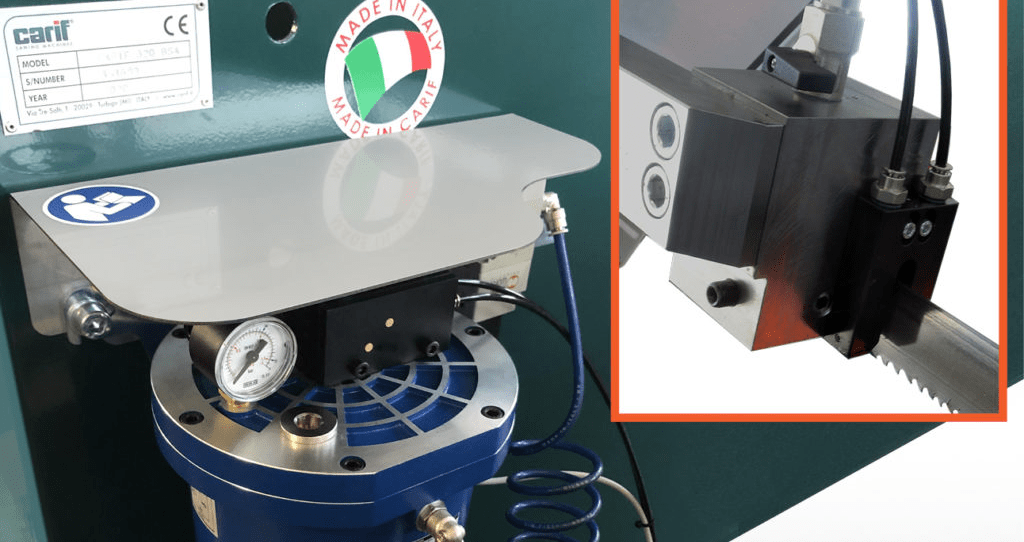

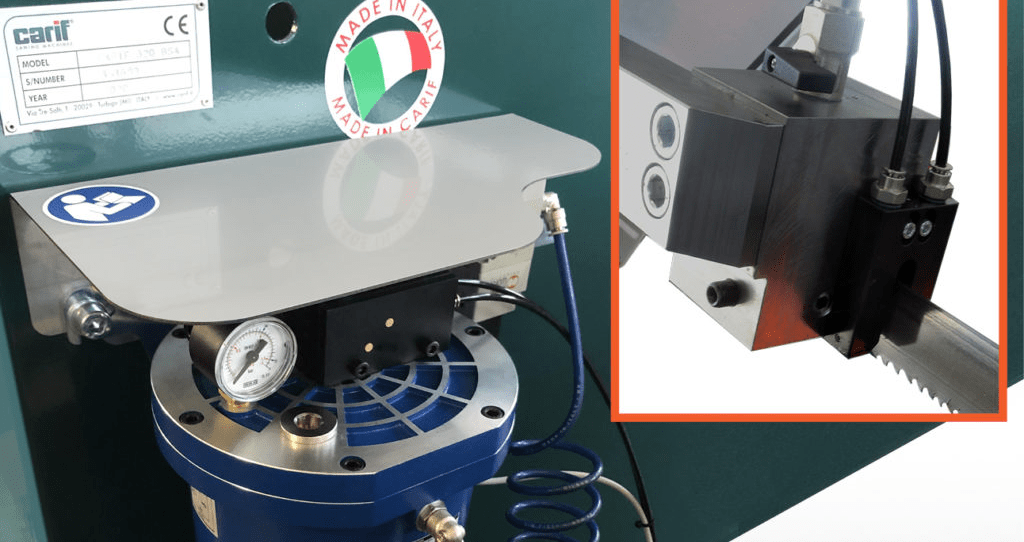

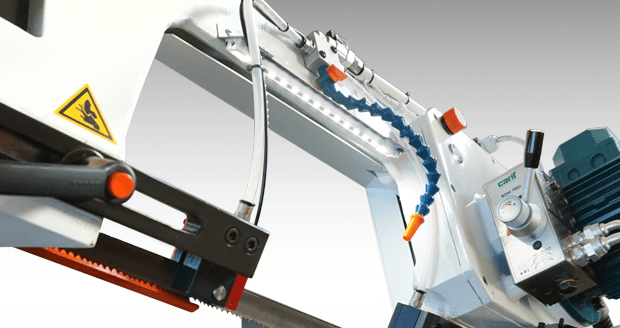

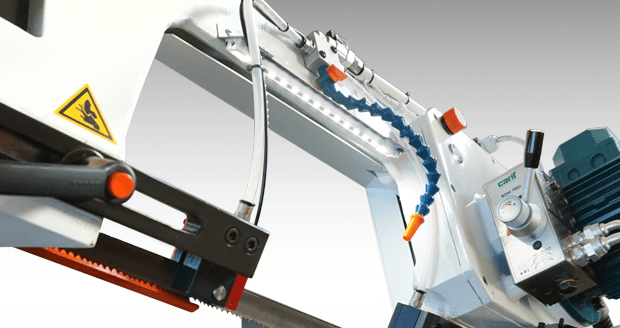

Air/oil lubrication system

This system provides precise blade lubrication by combining compressed air and oil, reducing wear and extending blade life. Ideal for clean cuts, even on demanding materials.

Laser cutting line

The laser line visually projects the cutting path onto the workpiece, allowing for rapid positioning and greater precision, particularly when mitering.

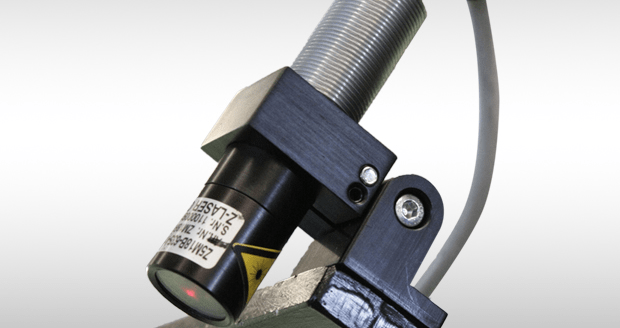

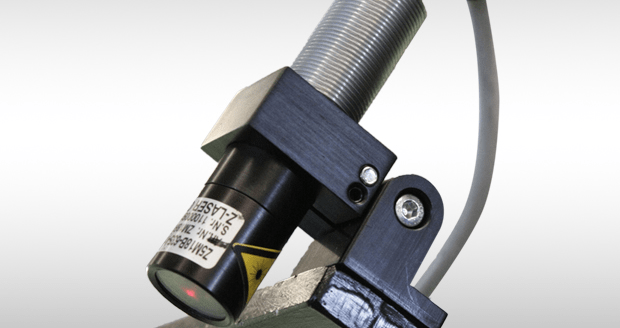

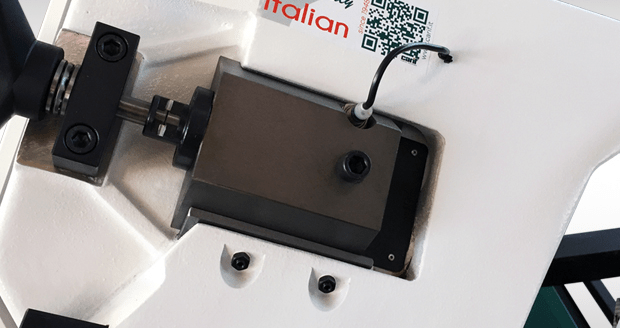

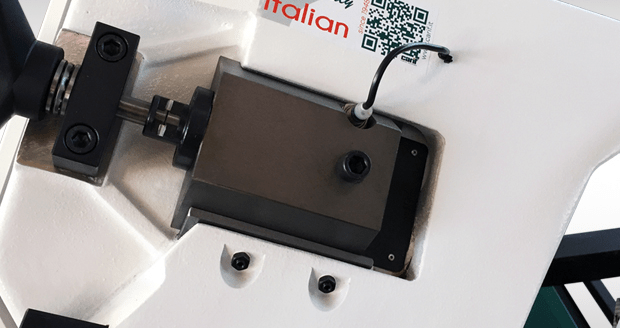

Blade rotation sensor

This smart sensor detects the actual rotation of the blade and allows secure automatic shutdown in the event of an anomaly or blockage. It helps to extend the tool's life and ensure operator safety.

Digital angle display

The cutting angle is digitally displayed on the integrated screen, providing an instant and accurate reading when setting the miter. An essential asset for precise repetitive cuts.

Work area lighting

Integrated lighting directly on the bow illuminates the cutting area, providing better visibility in low-light environments and improving alignment accuracy.