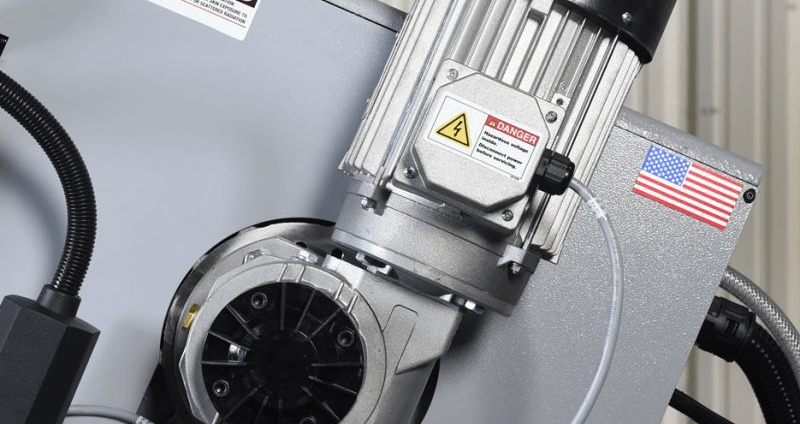

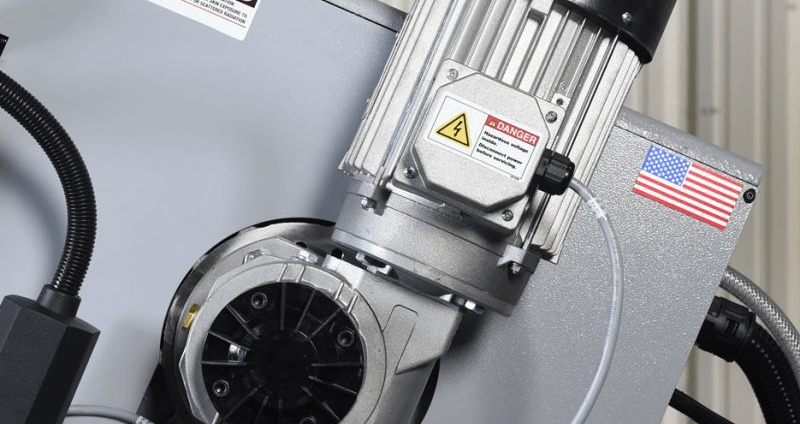

Drive control by variator

The blade speed can be adjusted directly from the operator control panel, without having to manually manipulate a pulley system. This allows for quick and precise adjustment depending on the material, while improving work efficiency.

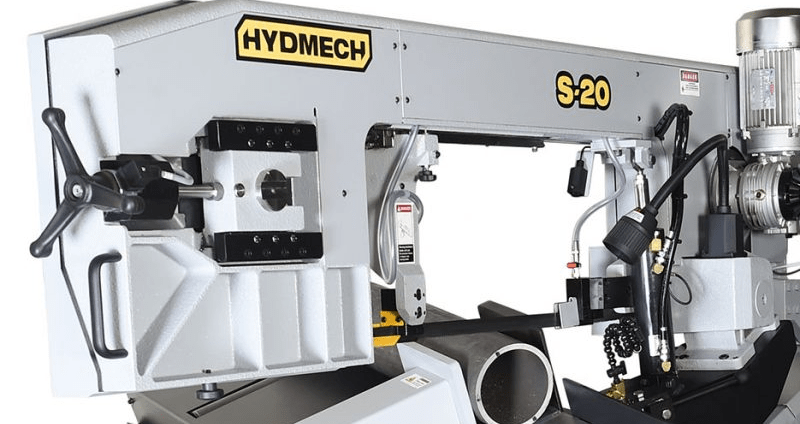

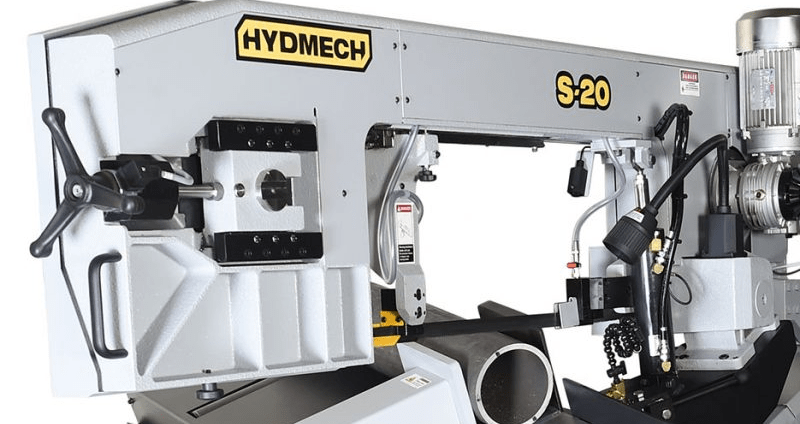

Movable blade guide arm

Mounted on linear bearings, the left guide arm can be moved easily and locked in position to adjust to the size of the workpiece. It ensures optimum stability during cutting.

Cast iron saw head

The massive cast iron head absorbs vibrations when cutting structural materials, reducing noise, extending blade life and improving cut quality.

Swivel head

The saw head can be swiveled up to 60 degrees, which greatly simplifies angled cuts and quick adjustments in the workshop.