Main features

- The extremely high efficiency achieves an impressive ratio between cutting speed and laser power.

- Cutting costs are up to 10 times lower than comparable CO2 lasers

- No expensive laser gases are needed, only nitrogen and oxygen are used as assist gases.

- No expensive turbines or other mechanical components with the source, unlike CO2 lasers which significantly reduces operating costs.

- Advanced anti-glare protection allows cutting of highly reflective materials.

- Automatic head height adjustment

- Liquid cooling ensures stability and minimizes the risk of damage to the header and fiber connector.

- The head lens is protected by a quartz window which protects against splashes from the cut material.

- The laser optics can be adjusted to suit specific materials.

- Fiber lasers do not require adjusting the mirrors in the resonator or supplying gas to it.

- They do not use turbines or vacuum pumps, which significantly reduces operating costs.

- The laser beam is guided by a fiber housed in the cable guides.

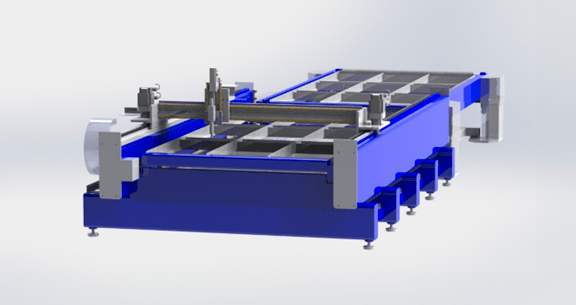

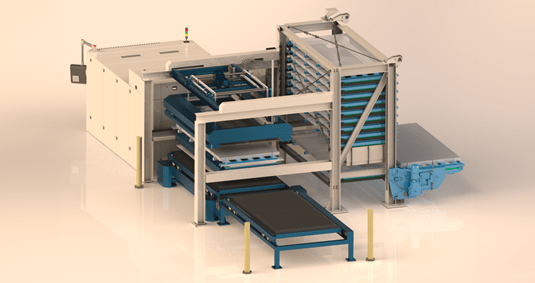

- Versions available with single vane, double vane or third vane system

- Pallet available with tube cutting system

- The software includes a NESTING option, which allows optimal distribution of details on the sheet.

- The system offers dynamic vector analysis, which achieves high performance for the most complex shapes.

- Online graphical visualization of laser operation

- Very low energy consumption

- The monolithic construction of the laser ensures high stability and precision.

- Rigid steel construction eliminates vibration and thermal drift.

- Compact, space-saving design - smallest footprint

- Self-supporting construction, eliminating the need for special foundations during installation

- Totally enclosed work area, protecting the operator from radiation in accordance with health and safety requirements.

- The machines are equipped with laser safety barriers.

- Cutting chamber equipped with an automatic extraction system for dust generated during cutting

- Easy import of GEO files for customers using machines produced by other companies

- The print head labels parts very quickly, making later identification easy.

- The scanning head allows existing details to be scanned, reducing project preparation time.

- Fiber laser prices are comparable to C02 cutting machines despite superior performance

- Automatic nozzle changing and cleaning system