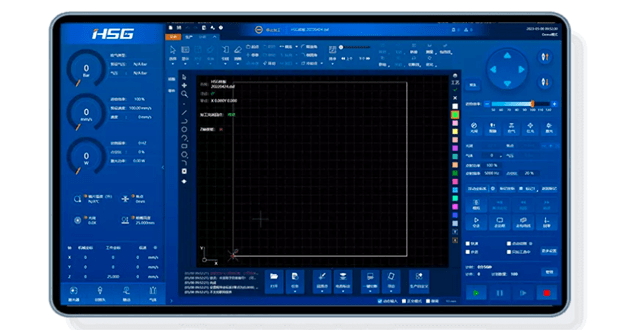

- By far HSG's most popular model

- High-strength monolithic structure, mechanically welded and standardized

- Aircraft grade aluminum high pressure gantry casting

- Efficient system of interchangeable tables

- Among the most affordable laser cutters with high quality in mind

- Affordable price of parts

- Appreciable performance, high profitability

- Sanyo or Panasonic brand motors and drives

- Alpha Wittenstein Pinions and Racks

- IPG resonator and Precitec heads (option)