Main features

- Order software

- POS 3000 3D graphic control with 22″ TFT Touch-Screen color screen movable by guide rail

- Radius function

- Remote maintenance via internet

- External programming

- Template system

- Measuring table 1700 mm U-shaped, segmented support plates with steel balls

- Side angle gauge right and left 1500 mm (outside)

- Suction plates in the measuring table, controlled by POS 3000

- 2 pneumatic retractable square arms mounted on the aisle side, controlled by program

- Gauge pin at the front

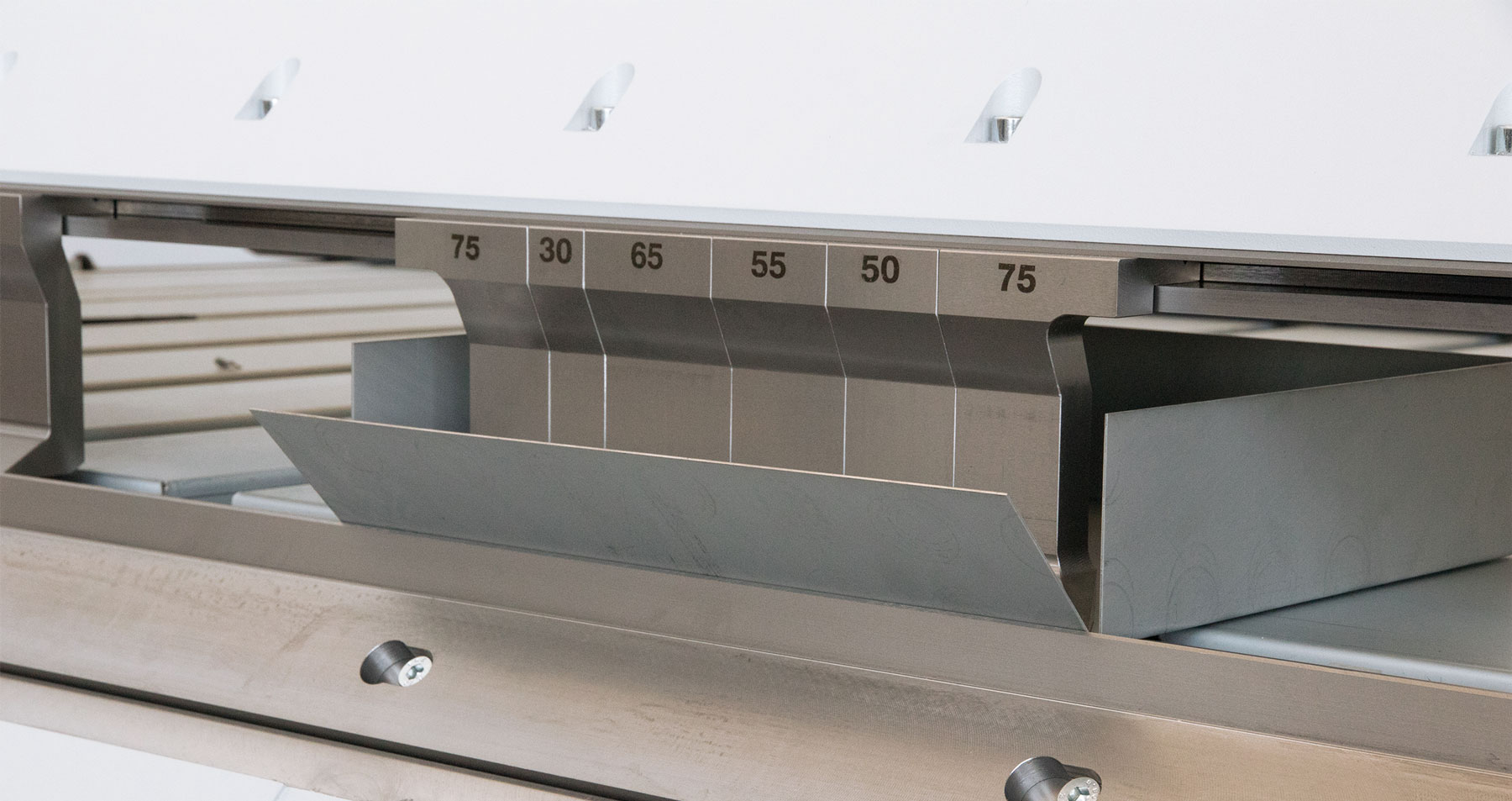

- Clamping beam

- Travel of the clamping beam: 850 mm

- Geometry of the clamping beam: 180°.

- Tool clamping, hydraulic

- Fully automatic tool changer for clamping beam tools for a maximum tool height of 400 mm

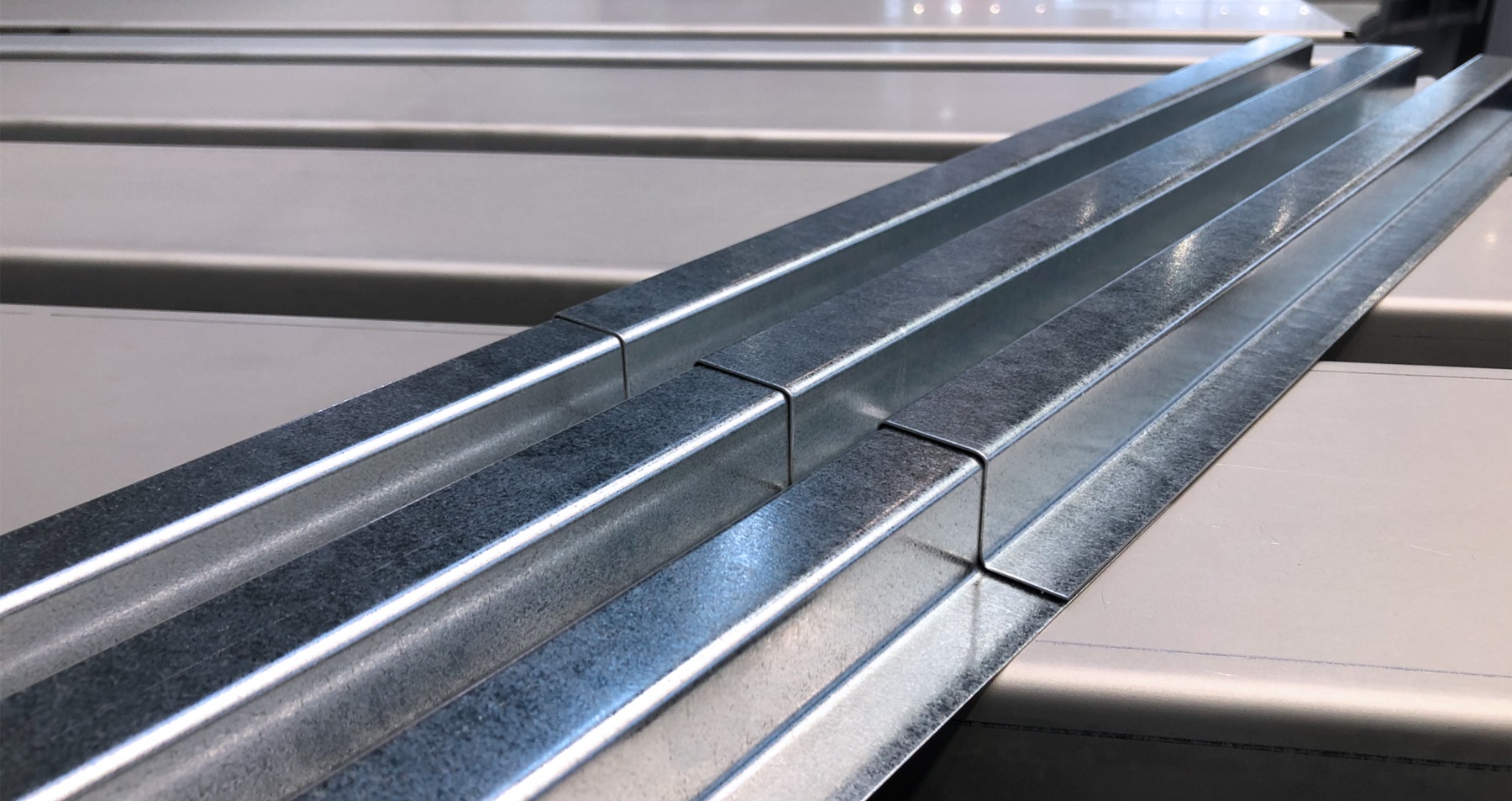

- Folding beam

- Up'n Down folding beam, with programmed control

- Tool clamping, pneumatic

- Motorized adjustment: 200 mm

- Central crowning device, motorized

- Motorized center point adjustment, converter control

- Work safety

- Protection by a light curtain for work at the rear

- Safety at the front thanks to a double sliding door

- Others

- Standard machine without tools

- Air conditioning on both electrical cabinets

- Footswitch with two pedals, including protective cover

- Anchor plates with dowels

- Tools

- Standard machine without tools