Main features

-

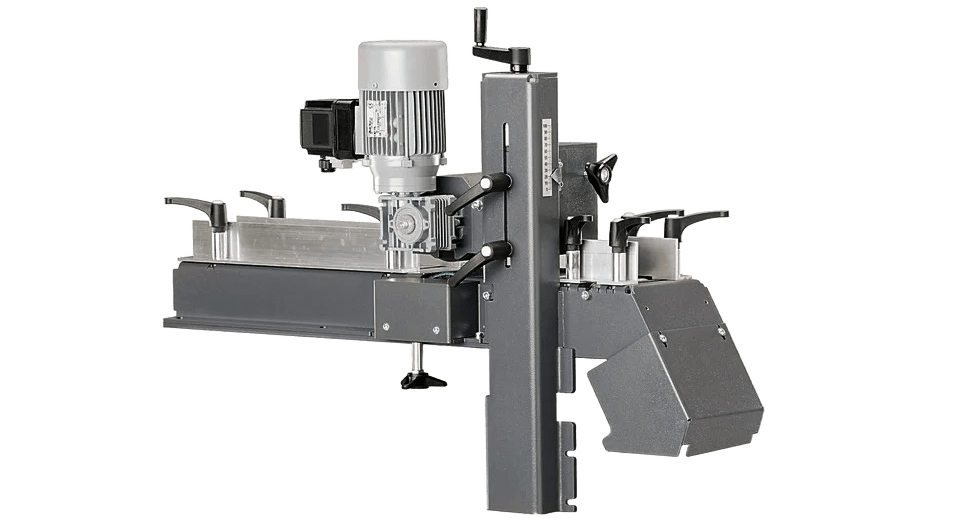

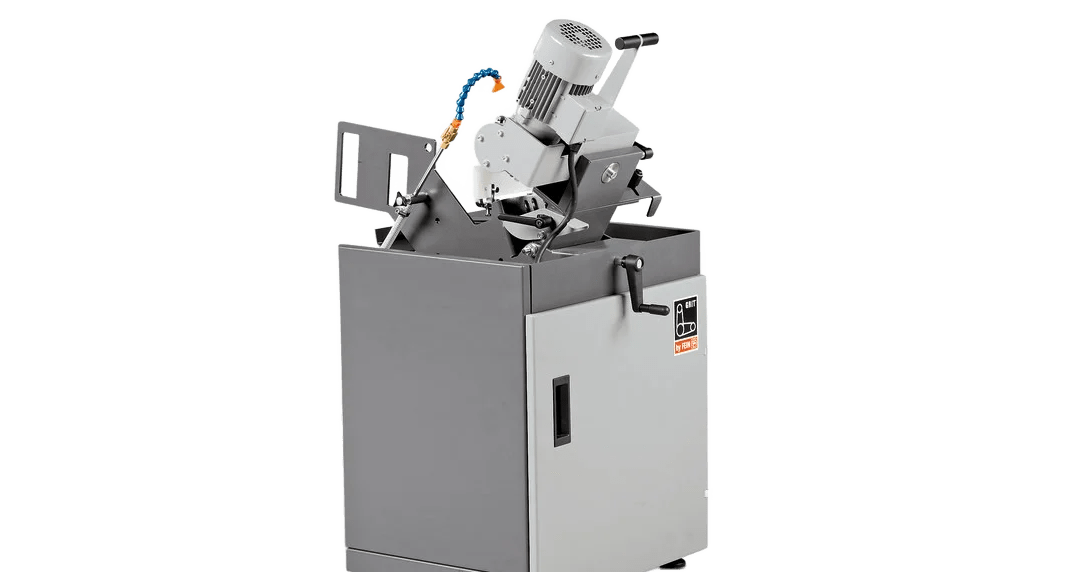

Compatible with extension modules for great versatility

-

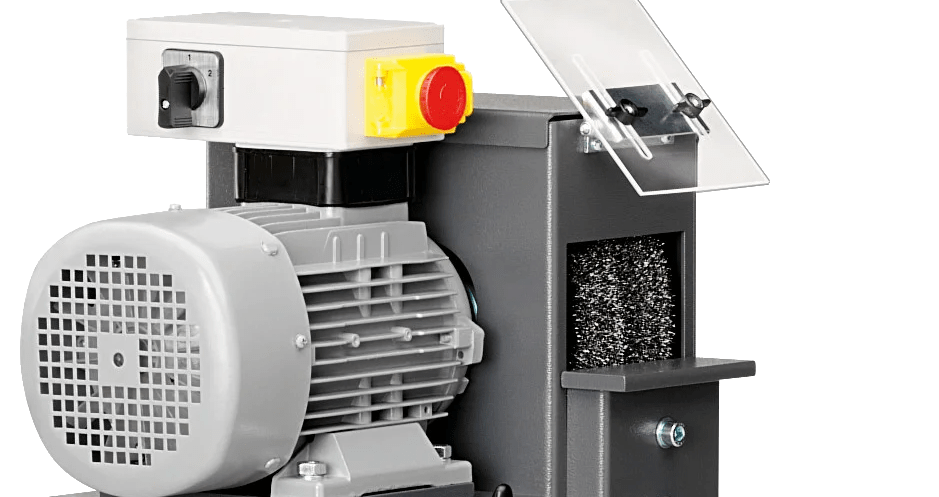

Heavy-duty three-phase motor, guaranteeing a constant speed

-

Two speeds optimal for metalworking: 1,500 / 3,000 rpm

-

Removable dust box for easy maintenance

-

Possible connection to an external vacuum cleaner

-

Polyurethane training disc

-

Individually adjustable working height

-

Patented belt tension system

-

Functioning quiet and low vibration