Full stroke full capacity hydraulic vice

Hydraulic vices offer a full opening for quick setup and effective clamping, even when cutting packages or various profiles. Time saving and solid hold guaranteed.

Integrated roller table

The entrance table incorporates free rollers, ensuring a smooth and stable loading material without the risk of jamming or falling between the rollers. Perfect for long or irregular pieces.

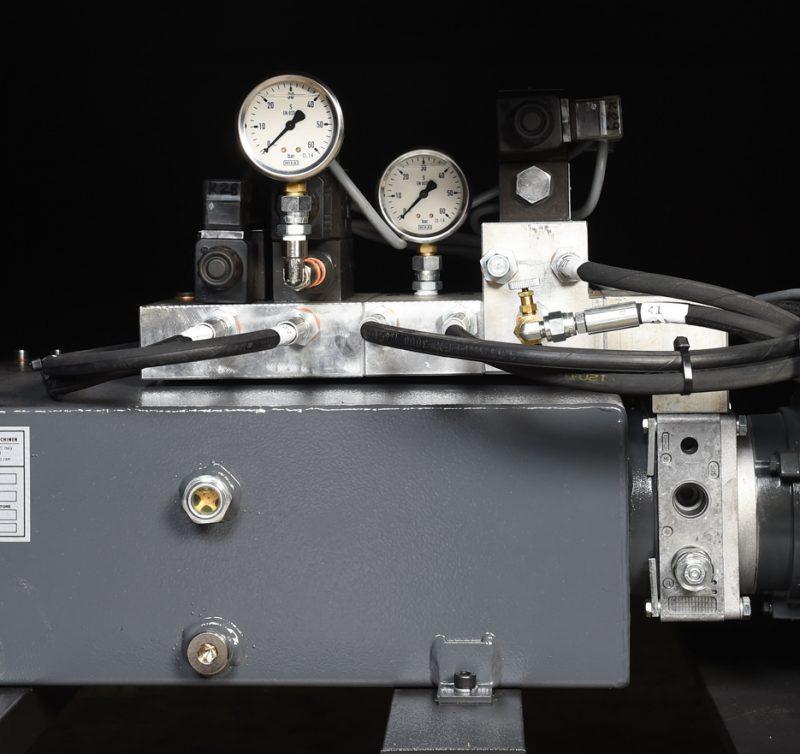

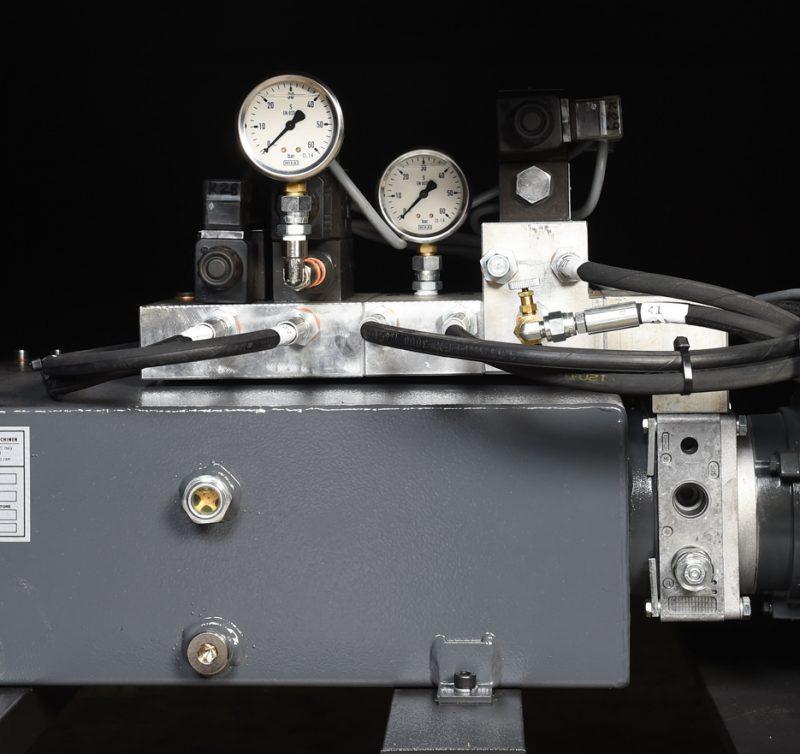

Hydraulics on demand

The hydraulic system automatically stops when inactive and restarts as soon as a command is activated. This allows reduce energy consumption and preserve the components.

Ball screw shuttle

The shuttle system is driven by ball screw and stepper motor, ensuring fast, smooth and precise positioning. The cast iron carriage allows for a Automatic indexing up to 28.5” per stroke, ideal for long repetitive cuts.